顶装式气相回收系统

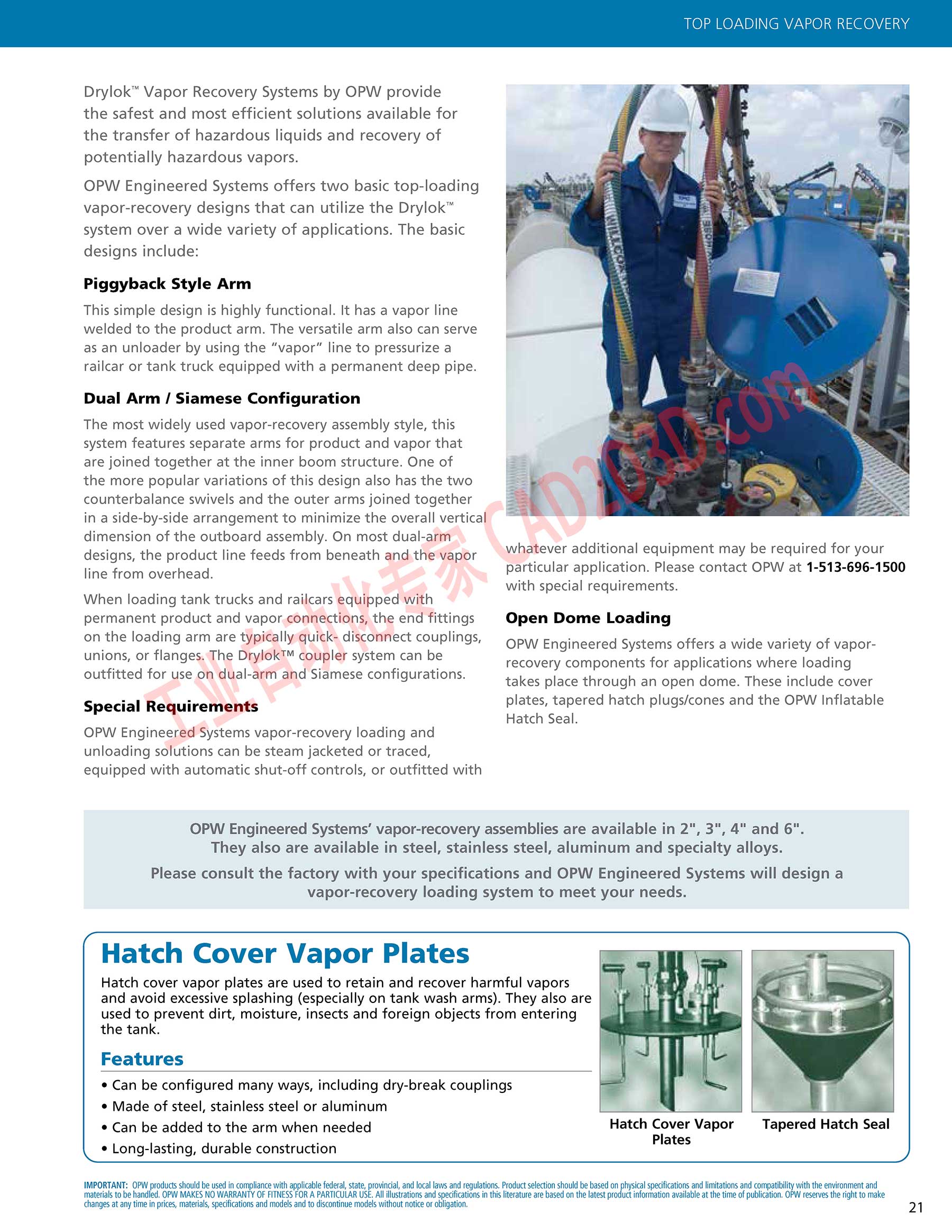

Drylok™ Vapor Recovery Systems by OPW provide

the safest and most efficient solutions available for

the transfer of hazardous liquids and recovery of

potentially hazardous vapors.

OPW Engineered Systems offers two basic top-loading

vapor-recovery designs that can utilize the Drylok™

system over a wide variety of applications. The basic

designs include:

Piggyback Style Arm

This simple design is highly functional. It has a vapor line

welded to the product arm. The versatile arm also can serve

as an unloader by using the “vapor” line to pressurize a

railcar or tank truck equipped with a permanent deep pipe.

Dual Arm / Siamese Configuration

The most widely used vapor-recovery assembly style, this

system features separate arms for product and vapor that

are joined together at the inner boom structure. One of

the more popular variations of this design also has the two

counterbalance swivels and the outer arms joined together

in a side-by-side arrangement to minimize the overall vertical

dimension of the outboard assembly. On most dual-arm

designs, the product line feeds from beneath and the vapor

line from overhead.

whatever additional equipment may be required for your

particular application. Please contact OPW at 1-513-696-1500

with special requirements.

When loading tank trucks and railcars equipped with

permanent product and vapor connections, the end fittings Open Dome Loading

on the loading arm are typically quick- disconnect couplings,

unions, or flanges. The Drylok™ coupler system can be

outfitted for use on dual-arm and Siamese configurations.

OPW Engineered Systems offers a wide variety of vapor-

recovery components for applications where loading

takes place through an open dome. These include cover

plates, tapered hatch plugs/cones and the OPW Inflatable

Special Requirements

Hatch Seal.

OPW Engineered Systems vapor-recovery loading and

unloading solutions can be steam jacketed or traced,

equipped with automatic shut-off controls, or outfitted with

OPW Engineered Systems’ vapor-recovery assemblies are available in 2", 3", 4" and 6".

They also are available in steel, stainless steel, aluminum and specialty alloys.

Please consult the factory with your specifications and OPW Engineered Systems will design a

vapor-recovery loading system to meet your needs.

Hatch Cover Vapor Plates

Hatch cover vapor plates are used to retain and recover harmful vapors

and avoid excessive splashing (especially on tank wash arms). They also are

used to prevent dirt, moisture, insects and foreign objects from entering

the tank.

Features

® Can be configured many ways, including dry-break couplings

Y

* Made of steel, stainless steel or aluminum i i ;

。Can be added to the arm when needed Hatch Cover Vapor Tapered Hatch Seal

. Plates

¢ Long-lasting, durable construction

IMPORTANT: OPW products should be used in compliance with applicable federal, state, provincial, and local laws and regulations. Product selection should be based on physical specifications and limitations and compatibility with the environment and

materials to be handled. OPW MAKES NO WARRANTY OF FITNESS FOR A PARTICULAR USE. All illustrations and specifications in this literature are based on the latest product information available at the time of publication. OPW reserves the right to make

changes at any time in prices, materials, specifications and models and to discontinue models without notice or obligation. 21

�