旋转接头拆装方法

O PWS

ENGENEERED SYSTEMS

a TiEED, company

Endura“ 8000 Series Swivel

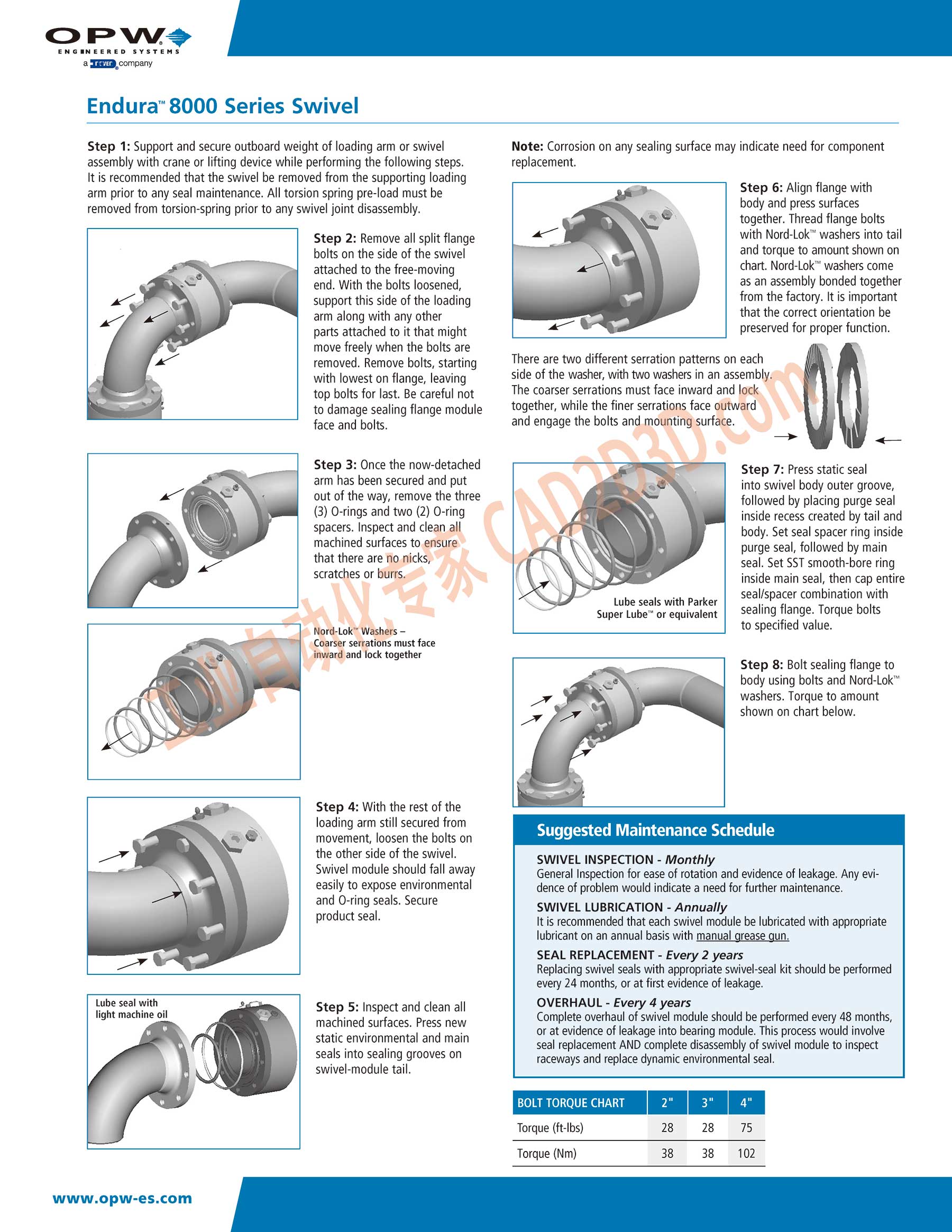

Step 1: Support and secure outboard weight of loading arm or swivel Note: Corrosion on any sealing surface may indicate need for component

assembly with crane or lifting device while performing the following steps. replacement.

It is recommended that the swivel be removed from the supporting loading

arm prior to any seal maintenance. All torsion spring pre-load must be

removed from torsion-spring prior to any swivel joint disassembly.

Step 6: Align flange with

body and press surfaces

together. Thread flange bolts

with Nord-Lok™ washers into tail

and torque to amount shown on

chart. Nord-Lok™ washers come

as an assembly bonded together

from the factory. It is important

that the correct orientation be

preserved for proper function.

Step 2: Remove all split flange

bolts on the side of the swivel

attached to the free-moving

end. With the bolts loosened,

support this side of the loading

arm along with any other

parts attached to it that might

move freely when the bolts are

removed. Remove bolts, starting

with lowest on flange, leaving

top bolts for last. Be careful not

to damage sealing flange module

face and bolts.

There are two different serration patterns on each

side of the washer, with two washers in an assemb

The coarser serrations must face inward and |

Step 3: Once the now-detached

arm has been secured and put

out of the way, remove the three

(3) O-rings and two (2) O-ring

spacers. Inspect and cle:

machined surfaces to

that there are no nick

scratches or

Step 7: Press static seal

into swivel body outer groove,

followed by placing purge seal

inside recess created by tail and

body. Set seal spacer ring inside

purge seal, followed by main

seal. Set SST smooth-bore ring

inside main seal, then cap entire

seal/spacer combination with

sealing flange. Torque bolts

to specified value.

Lube seals with Parker

Super Lube™ or equivalent

Step 8: Bolt sealing flange to

body using bolts and Nord-Lok™

washers. Torque to amount

shown on chart below.

Step 4: With the rest of the

loading arm still secured from

movement; loosenthe boltsion Suggested Maintenance Schedule

the other side of the swivel. SWIVEL INSPECTION - Monthly

Swivel module should fall away General Inspection for ease of rotation and evidence of leakage. Any evi-

easily to expose environmental dence of problem would indicate a need for further maintenance.

and O-ring seals. Secure SWIVEL LUBRICATION - Annually

product seal. It is recommended that each swivel module be lubricated with appropriate

lubricant on an annual basis with manual grease gun.

SEAL REPLACEMENT - Every 2 years

Replacing swivel seals with appropriate swivel-seal kit should be performed

every 24 months, or at first evidence of leakage.

Step 5: Inspect and clean all OVERHAUL - Every 4 years

macfiined su}:faces Press new Complete overhaul of swivel module should be performed every 48 months,

statieiehigifofimeh | ii or at evidence of leakage into bearing module. This process would involve

li li seal replacement AND complete disassembly of swivel module to inspect

seals into sealing grooves on raceways and replace dynamic environmental seal.

swivel-module tail.

BOLT TORQUE CHART -n

Torque (ft-lbs)

Torque (Nm) 38 38 102

Lube seal with

light machine oil

www.opw-es.com

�