旋转接头拆装方法

Endura™ 8000 Maintenance

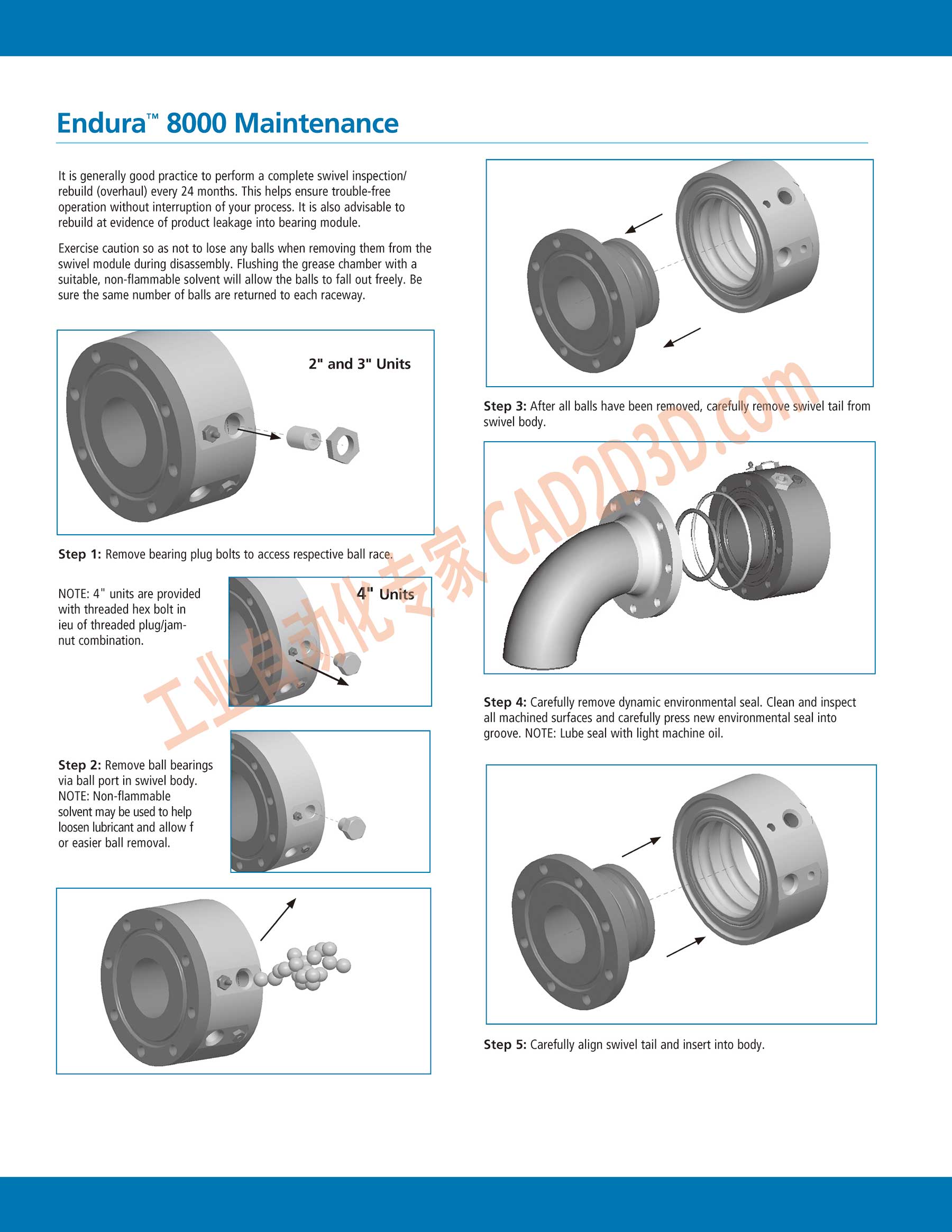

It is generally good practice to perform a complete swivel inspection/

rebuild (overhaul) every 24 months. This helps ensure trouble-free

operation without interruption of your process. It is also advisable to

rebuild at evidence of product leakage into bearing module.

Exercise caution so as not to lose any balls when removing them from the

swivel module during disassembly. Flushing the grease chamber with a

suitable, non-flammable solvent will allow the balls to fall out freely. Be

sure the same number of balls are returned to each raceway.

2" and 3" Units

-0

Step 1: Remove bearing plug bolts to access respective ball race.

NOTE: 4" units are provided

with threaded hex bolt in

ieu of threaded plug/jam-

nut combination.

Step 2: Remove ball bearings

via ball port in swivel body.

NOTE: Non-flammable

solvent may be used to help

loosen lubricant and allow f

or easier ball removal.

Step 3: After all balls have been removed, carefully remove swivel tail from

swivel body.

Step 4: Carefully remove dynamic environmental seal. Clean and inspect

all machined surfaces and carefully press new environmental seal into

groove. NOTE: Lube seal with light machine oil.

Step 5: Carefully align swivel tail and insert into body.

�