了解流量系数(Cv)如何影响阀门尺寸。在我们今天的指南中探索它们的计算、在流体动力学中的重要性、应用等!

Have you ever wondered how to ensure the optimal performance of fluid systems?

您是否想过如何确保流体系统的最佳性能?

One secret lies in selecting the right valve size, and the key to achieving this is understanding the flow coefficient (Cv).

一个秘诀在于选择正确的阀门通径,而实现这一点的关键是了解流量系数(Cv)。

A precise understanding of Cv is crucial for engineers and technicians alike, as it helps determine the appropriate

valve size for a specific application, thus avoiding potential issues and inefficiencies.

精确了解Cv对于工程师和技术人员至关重要,因为它有助于确定特定应用的适当阀门尺寸,从而避免潜在问题和效率低下。

In this guide, we will dive into the concept of flow coefficient, its variables, and how it plays a vital role in valve sizing.

在本指南中,我们将深入了解流量系数的概念,它的变量,以及它如何在阀门定径中发挥重要作用。

We will also explore how to calculate Cv for different media types, such as liquids, gases, and steam, and discuss the importance of differential pressure in valve sizing.

我们还将探讨如何计算不同介质类型(如液体、气体和蒸汽)的Cv,并讨论差压在阀门尺寸确定中的重要性。

Finally, we will compare Cv and Kv, two commonly used flow coefficients, and provide guidance on choosing the right flow coefficient for your needs.

最后,我们将比较两种常用的流量系数Cv和Kv,并为您选择合适的流量系数提供指导。

Understanding Flow Coefficient (Cv) 了解流量系数(Cv)

The valve flow coefficient, often denoted as Cv, measures the fluid flow rate through a control valve.

阀流量系数,通常表示为Cv,测量通过控制阀的流体流速。

It is a crucial factor in valve sizing as it helps determine the appropriate valve size for optimal performance.

它是阀门尺寸的一个关键因素,因为它有助于确定最佳性能的适当阀门尺寸。

The valve flow coefficient Cv is expressed as a percentage of the maximum possible flow rate, considering the corresponding pressure drop.

考虑到相应的压降,阀门流量系数Cv表示为最大可能流量的百分比。

Cv, also known as ‘Valve Flow Coefficient’, is a practical definition used to measure the flow rate of water.

Cv,也称为“阀门流量系数”,是一个用于测量水流量的实用定义。

It quantifies the rate at which a valve can pass a certain volume of water at a particular pressure drop.

它量化了阀门在特定压降下通过一定体积水的速率。

The measurement typically occurs when water with a temperature of 60 °F (16 °C) flows through a valve with 1 psi (6.9 kPa) pressure drop across it.

测量通常发生在温度为60 °F(16 °C)的水流过阀门时,其压降为1 psi(6.9 kPa)。

A valve’s Cv rating directly affects its flow capacity, with higher ratings resulting in greater water flow capacity.

阀门的Cv额定值直接影响其流量,额定值越高,水流量越大。

The Cv value is indicated on the valve’s product description or specifications label and is utilised to determine the correct sized valve based on the required flow rate and pressure drop.

Cv值显示在阀门的产品说明或规格标签上

If required, it is advisable to select a valve with a Cv value higher than the calculated one. This provides you with a greater flow rate and it safeguards against potential changes in pressure or flow rate.

如果需要,建议选择Cv值高于计算值的阀门。这为您提供了更大的流量,并防止压力或流量的潜在变化。

Valve Flow Coefficient Variables阀门流量系数变量

Several factors influence the flow coefficient of a valve, including:

有几个因素影响阀门的流量系数,包括:

- The valve’s internal geometry

瓣膜的内部几何结构 - Fluid properties, such as viscosity, density, and temperature

流体属性,如粘度、密度和温度 - The valve’s size

阀门尺寸 - The presence or absence of piping reducers adjacent to the valve

阀门附近是否有管道异径管

All of these factors play a role in determining the flow coefficient.

所有这些因素都在确定流量系数中起作用。

The desired flow rate also influences the flow coefficient of a valve.

所需的流率也影响阀的流量系数。

Higher flow rates necessitate larger valves with higher flow coefficients to ensure enough flow capacity for the system requirements.

更高的流速需要具有更高流量系数的更大阀门,以确保满足系统要求的足够流量。

Thus, an accurate understanding of the fluid properties and valve characteristics is essential in determining the correct Cv value for a specific application.

因此,准确理解流体特性和阀门特性对于确定特定应用的正确Cv值至关重要。

Pressure Drop and Cv 压降和Cv

Pressure drop is a critical factor in calculating Cv and plays a significant role in valve sizing.

压降是计算Cv的一个关键因素,在阀门选型中起着重要作用。

The desired pressure is essential to consider, as pressure drop is the difference in fluid pressure between the inlet and outlet of the valve, often resulting from resistance to flow in the valve and piping system.

所需的压力是必须考虑的,因为压降是阀门入口和出口之间的流体压力差,通常由阀门和管道系统中的流动阻力引起。

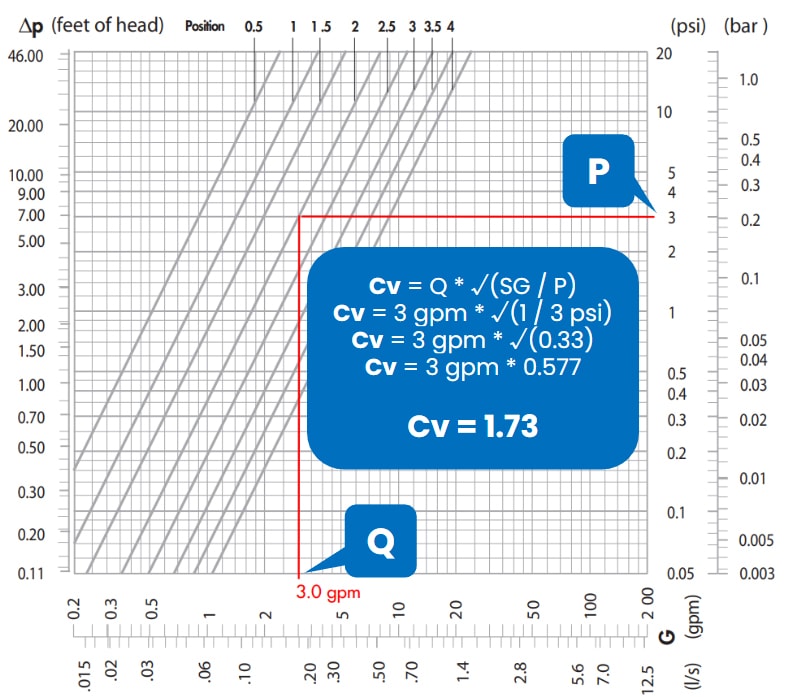

It can be determined by either consulting standard graphs or by comparing the upstream fluid pressure and downstream pressure.

它可以通过参考标准图表或通过比较上游流体压力和下游压力来确定。

Taking pressure drop into account when calculating Cv is essential for selecting the right valve size, as it directly influences the flow capacity of the valve.

在计算Cv时考虑压降对于选择正确的阀门通径至关重要,因为它直接影响阀门的通流能力。

By accurately calculating pressure drop, engineers can ensure optimal valve sizing and avoid potential issues, such as:

通过准确计算压降,工程师可以确保最佳的阀门尺寸,避免潜在的问题,例如:

- Choked flow阻流

- Inadequate flow capacity流量不足

- System inefficiencies系统效率低下

- Damage损害

Calculating Flow Coefficient for Different Media 不同介质的流量系数计算

Different media types, such as liquids, gases, and steam, require specific calculations for flow coefficient due to their unique physical properties and behavior.

不同的介质类型,如液体、气体和蒸汽,由于其独特的物理性质和行为,需要特定的流量系数计算。

These calculations take into account factors such as density, temperature, and pressure drop, ensuring accurate valve sizing for each type of fluid.

这些计算考虑了密度、温度和压降等因素,确保了每种流体的阀门尺寸准确。

By understanding the distinct formulas for each medium, engineers can optimise the performance of their fluid systems and avoid potential issues associated with improper valve sizing.

通过了解每种介质的不同配方,工程师可以优化其流体系统的性能,避免与阀门尺寸不当相关的潜在问题。

In the following subsections, we will look into the specific calculations for the flow coefficient for liquids.

在下面的小节中,我们将研究液体流动系数的具体计算。

Gaining a thorough understanding of these formulas will enable you to accurately size control valves for various media types, ensuring optimal system performance and efficiency.

深入了解这些公式将使您能够针对各种介质类型准确地确定控制阀的尺寸,从而确保最佳的系统性能和效率。

Flow Coefficient for Liquids 液体的流量系数

The flow coefficient for liquids is based on the flow rate of water in GPM at 60°F and 1 psi pressure drop across the valve.

液体的流量系数基于60°F时水的流速(单位:GPM)和阀门上的1 psi压降。

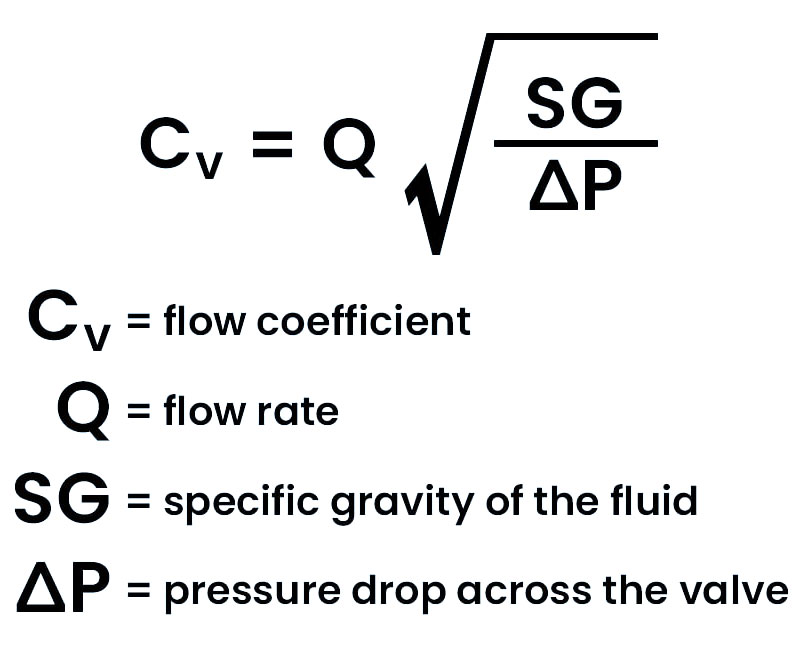

The formula for calculating the flow coefficient (Cv) for liquids is:

计算液体流量系数(Cv)的公式为:

Cv = Q * sqrt(SG / P)

Q is the flow rate in gallons per minute (GPM)

Q是流量,单位为加仑/分钟(GPM)

SG is the specific gravity of the fluid

SG是流体的比重

P is the pressure drop in pounds per square inch (psi).

P是以磅/平方英寸(psi)为单位的压降。

An increased specific gravity leads to an increased flow rate(博主表示不理解), and a higher pressure drop results in a decreased flow coefficient.

增加的比重导致增加流量,并且更高的压降导致降低的流量系数。

By understanding this formula and the significance of specific gravity and pressure drop, engineers can accurately size valves for liquids, ensuring optimal performance and avoiding potential issues such as inadequate flow capacity or excessive pressure drop.

通过了解这个公式以及比重和压降的重要性,工程师可以准确地确定液体阀门的尺寸,确保最佳性能并避免潜在的问题,如流量不足或压降过大。

This knowledge is essential for the proper design and operation of fluid systems that handle liquids.

这些知识对于正确设计和操作处理液体的流体系统至关重要。

Control Valve Sizing and Flow Capacity 控制阀尺寸和流量

Proper valve sizing is essential for optimal performance, and flow capacity plays a significant role in determining the correct valve size.

正确的阀门通径对于最佳性能至关重要,而流量在确定正确的阀门通径方面起着重要作用。

Flow capacity is the maximum amount of fluid that can pass through a valve and is determined by utilising the flow coefficient (Cv) of the valve, the pressure drop across the valve, and the fluid density.

流量是可以通过阀门的流体的最大量,并且通过利用阀门的流量系数(Cv)、通过阀门的压降和流体密度来确定。

By understanding the relationship between flow capacity and valve size, engineers can ensure the correct valve size is selected for a given flow rate and pressure drop.

通过了解流量和阀门通径之间的关系,工程师可以确保为给定的流量和压降选择正确的阀门通径。

Undersized vs. Oversized Valves 尺寸过小的瓣膜与尺寸过小的瓣膜

An undersized valve has restricted flow capacity and could potentially cause a higher pressure drop across the valve, leading to poor performance and potential harm to the system.

尺寸过小的阀门流量有限,可能会导致阀门上的压降更高,从而导致性能下降,并对系统造成潜在危害。

Conversely, an oversized valve may have inadequate controllability and can exacerbate issues within the system, in addition to being more costly.

相反,尺寸过大的阀可能具有不足的可控性,并且除了成本更高之外,还可能加剧系统内的问题。

Therefore, it is crucial to select the right valve size for a given application to ensure optimal performance and efficiency.

因此,为特定应用选择正确的阀门通径至关重要,以确保最佳性能和效率。

By understanding the drawbacks of using undersized and oversized valves, engineers can make informed decisions when selecting the appropriate valve size for their fluid systems.

通过了解使用过小和过大阀门的缺点,工程师可以在为流体系统选择合适的阀门尺寸时做出明智的决定。

This knowledge helps to prevent potential issues and inefficiencies associated with improper valve sizing, ensuring optimal system performance and longevity.

这些知识有助于防止与阀门尺寸不当相关的潜在问题和效率低下,确保最佳的系统性能和寿命。

Differential Pressure and Valve Sizing 压差和阀门尺寸

Differential pressure, or the difference between inlet pressure and outlet pressure, is a crucial factor in valve sizing and flow capacity calculations. By taking differential pressure into account, engineers can:

压差,或入口压力和出口压力之间的差,是阀门尺寸和流量计算的关键因素。通过考虑压差,工程师可以:

Accurately size valves for a given flow rate and pressure drop

根据给定的流量和压降精确确定阀门尺寸

Ensure optimal valve performance

确保最佳阀门性能

Avoid potential issues such as choked flow or inadequate flow capacity.

避免潜在的问题,如阻塞流量或流量不足。

Understanding the importance of differential pressure in valve sizing and flow capacity calculations helps engineers design and operate fluid systems that function optimally.

了解差压在阀门尺寸和流量计算中的重要性有助于工程师设计和操作功能最佳的流体系统。

By selecting the appropriate valve size based on differential pressure, engineers can ensure the efficient operation of their fluid systems and prevent potential issues associated with improper valve sizing.

通过根据压差选择适当的阀门通径,工程师可以确保其流体系统的有效运行,并防止与阀门尺寸不当相关的潜在问题。

Cv and Kv: Comparing Flow Coefficients Cv和Kv:流量系数Cv和Kv比较

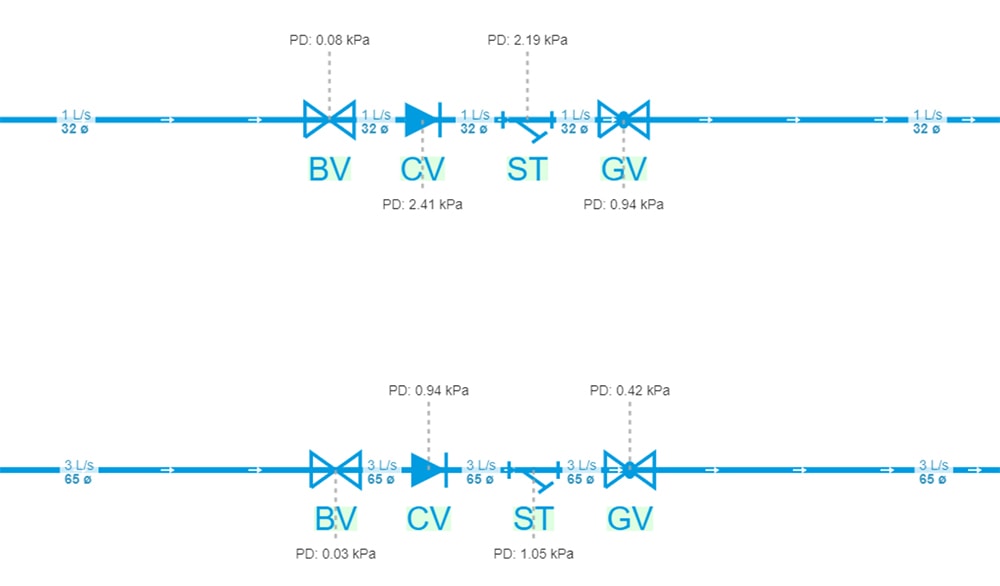

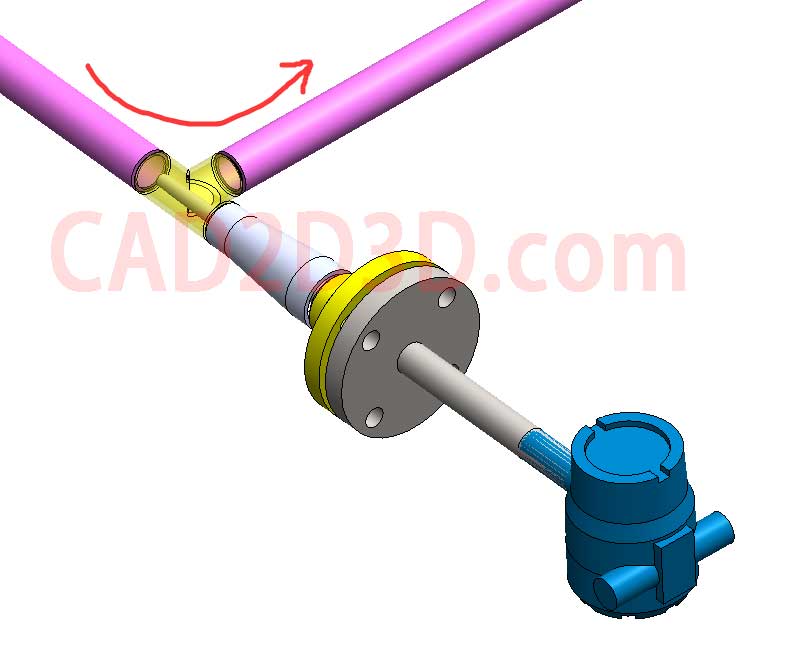

This image shows how the pressure drop across a valve changes as the pipe size, flow rate, and velocity change, due to the Cv/Kv value.

这张图片显示了阀门上的压降如何随着管道尺寸、流量和速度的变化而变化,这是由于Cv/Kv值的影响。

Even though they both differ in units and measurement systems, Cv and Kv are both flow coefficients used to measure fluid flow rate through a valve.

尽管它们在单位和测量系统上都不同,但Cv和Kv都是用于测量通过阀的流体流速的流量系数。

Cv is primarily utilised in the Imperial unit system and denotes the quantity of US gallons per minute of water at 60 °F that will flow through a valve with a pressure drop of 1 psi.

Cv主要用于英制单位系统,表示在60 °F下每分钟流经压力降为1 psi的阀门的美国加仑数。

Conversely, Kv is employed in the metric unit system and indicates the amount of water that can pass through a valve in cubic meters per hour with a pressure drop of one bar.

相反,Kv用于公制单位系统,表示在压降为1 bar的情况下,每小时可以通过阀门的水量(立方米)。

In the following subsections, we will provide the conversion formulas for Cv and Kv, helping users switch between the two flow coefficients.

在下面的小节中,我们将提供Cv和Kv的转换公式,帮助用户在两个流量系数之间切换。

By understanding the differences between Cv and Kv and their respective units and measurement systems, engineers can accurately size valves for various applications, ensuring optimal system performance and efficiency.

通过了解Cv和Kv之间的差异及其各自的单位和测量系统,工程师可以根据各种应用准确地确定阀门的尺寸,确保最佳的系统性能和效率。

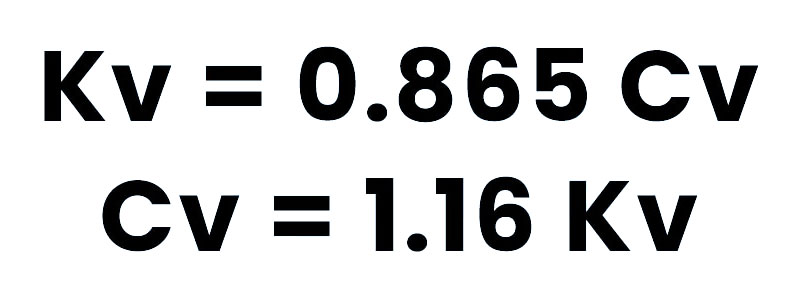

Conversion Formulas for Cv and Kv Cv和Kv的换算公式

Kv = 0.865 Cv

Cv = 1.16 Kv

To help users switch between Cv and Kv, the conversion formulas are provided: Kv = 0.865 Cv and Cv = 1.16 Kv.

为了帮助用户在Cv和Kv之间切换,提供了转换公式:Kv = 0.865 Cv和Cv = 1.16 Kv。

These formulas allow users to easily convert between the two flow coefficients, ensuring accurate valve sizing regardless of the measurement system used.

这些公式使用户能够轻松地在两个流量系数之间进行转换,从而确保无论使用何种测量系统都能精确测量阀门尺寸。

For instance, if the Cv of a valve is 10, then the Kv of the valve is 8.65.

例如,如果阀门的Cv为10,则阀门的Kv为8.65。

By understanding these conversion formulas, engineers can accurately size valves for various applications, regardless of the measurement system used.

通过了解这些转换公式,工程师可以根据各种应用准确地测量阀门的尺寸,而不管使用什么测量系统。

This knowledge ensures optimal system performance and efficiency, preventing potential issues associated with improper valve sizing.

这些知识确保了最佳的系统性能和效率,防止了与阀门尺寸不当相关的潜在问题。

Choosing the Right Flow Coefficient 选择正确的流量系数

Selecting the appropriate flow coefficient is essential for accurate valve sizing and optimal system performance.

选择合适的流量系数对于精确的阀门尺寸和最佳的系统性能至关重要。

The type of fluid, the pressure drop across the valve, and the desired flow rate should be taken into account when selecting a flow coefficient.

在选择流量系数时,应考虑流体类型、阀门两端的压降以及所需的流速。

By accurately calculating Cv or Kv values, engineers can ascertain the size of the valve required for a specific application.

通过精确计算Cv或Kv值,工程师可以确定特定应用所需的阀门尺寸。

By choosing the right flow coefficient, engineers can ensure optimal valve sizing and system performance, preventing potential issues associated with improper valve sizing.

通过选择正确的流量系数,工程师可以确保最佳的阀门尺寸和系统性能,防止与阀门尺寸不当相关的潜在问题。

This knowledge is essential for the proper design and operation of fluid systems, as it helps to avoid potential issues such as choked flow or inadequate flow capacity.

这些知识对于流体系统的正确设计和操作至关重要,因为它有助于避免潜在的问题,如阻塞流量或流量不足。

Conclusion 结论

Throughout this guide, we have explored the importance of understanding the flow coefficient and its crucial role in valve sizing for optimal system performance.

在本指南中,我们探讨了理解流量系数的重要性及其在阀门尺寸优化系统性能中的关键作用。

By comprehending the variables affecting valve flow coefficient, calculating Cv values for different media types, and considering differential pressure in valve sizing, engineers can design and operate fluid systems that function efficiently and effectively.

通过了解影响阀门流量系数的变量,计算不同介质类型的Cv值,并考虑阀门尺寸的压差,工程师可以设计和操作高效和有效运行的流体系统。

Furthermore, recognising the differences between Cv and Kv flow coefficients and their respective units and measurement systems ensures accurate valve sizing across various applications.

此外,认识到Cv和Kv流量系数及其各自单位和测量系统之间的差异,可确保在各种应用中准确测量阀门尺寸。

参考文献:https://www.h2xengineering.com/blogs/flow-coefficient-guide-valve-sizing/

转载请注明:

文章作者: 尚延伟 原文链接:https://www.cad2d3d.com/post- 2048 .html

可能感兴趣的文章

更多最新发布: 化工装备

-

GB 50093 自动化仪表工程施工及质量验收规范 温度、压力取源部件安装规定、条文解释说明及案例解析

-

电气装置应接地,螺栓应有防松装置,接线端子及紧固件应涂电力复合脂

-

钢厂作业人员必备!饱和水蒸气球罐(球形蒸汽蓄热器)技术参数、生产制造过程、实物图及潜在失效模式分析

钢厂作业人员必备!饱和水蒸气球罐(球形蒸汽蓄热器)技术参数、生产制造过程、实物图及潜在失效模式分析

-

绝了!LNG 工厂的终极神器竟然是自行车,电器全封杀,机械的含金量还在上升

绝了!LNG 工厂的终极神器竟然是自行车,电器全封杀,机械的含金量还在上升

-

LPG、丙烷、丁烷等装卸车用 STANAG 3756 干式分离阀(干式快速接头)厂家品牌及产品介绍

LPG、丙烷、丁烷等装卸车用 STANAG 3756 干式分离阀(干式快速接头)厂家品牌及产品介绍

-

LNG 罐箱(罐式集装箱) P&ID、阀门清单、3D效果图、实物图和装卸方法

LNG 罐箱(罐式集装箱) P&ID、阀门清单、3D效果图、实物图和装卸方法

-

API 610 离心泵的泵型 OH1 和 OH2 的区别、图示及对应的实物图

API 610 离心泵的泵型 OH1 和 OH2 的区别、图示及对应的实物图

-

![你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]](https://www.cad2d3d.com/uploads/202601/ranqibiao.jpg) 你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]

你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]

德力西电磁阀4v210-08换向阀24V气动控制阀220v二位五通电子阀12V

德力西电磁阀4v210-08换向阀24V气动控制阀220v二位五通电子阀12V  TWSANS台匠山耐斯4v210-08气动电磁阀24v控制阀二位五通气阀ac220

TWSANS台匠山耐斯4v210-08气动电磁阀24v控制阀二位五通气阀ac220  4V210-08气缸电磁阀4V110气动控制阀AC220v二位五通换向气阀DC24V

4V210-08气缸电磁阀4V110气动控制阀AC220v二位五通换向气阀DC24V

管道热电阻(热电偶)安装方法,温度变送器安装位置,一图胜过千言万语

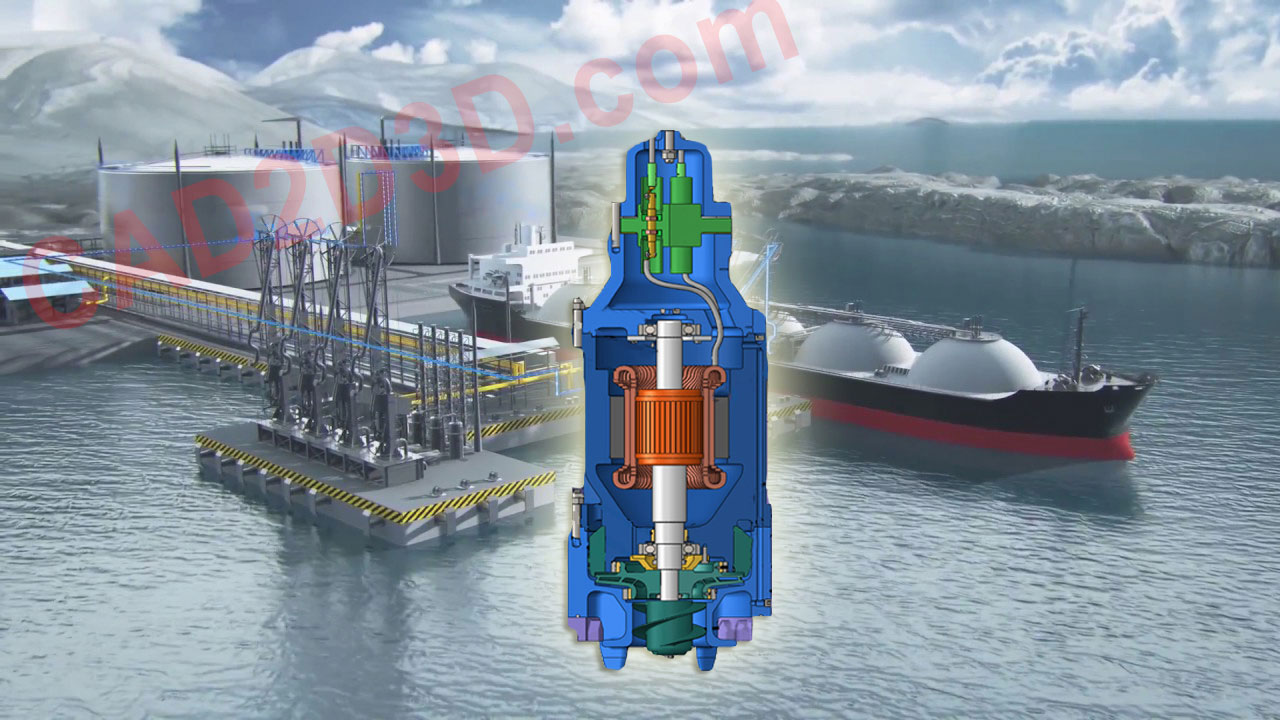

管道热电阻(热电偶)安装方法,温度变送器安装位置,一图胜过千言万语 LNG罐内泵(低温潜液泵)内部构造、结构组成和运行原理

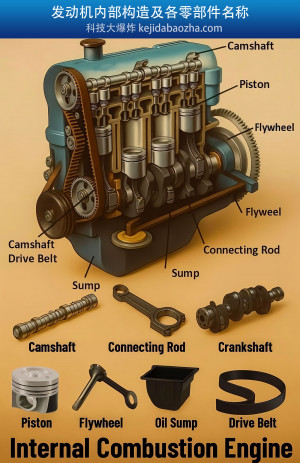

LNG罐内泵(低温潜液泵)内部构造、结构组成和运行原理 内燃机发动机内部构造,各零部件名称中英文对炸

内燃机发动机内部构造,各零部件名称中英文对炸 地球大气层各层高度及对应的航天器高度,大气层及航天器名称中英为对照,一图胜过千言万语

地球大气层各层高度及对应的航天器高度,大气层及航天器名称中英为对照,一图胜过千言万语 针型阀 全称针型截止阀 Needle Valve 内部结构和运行原理

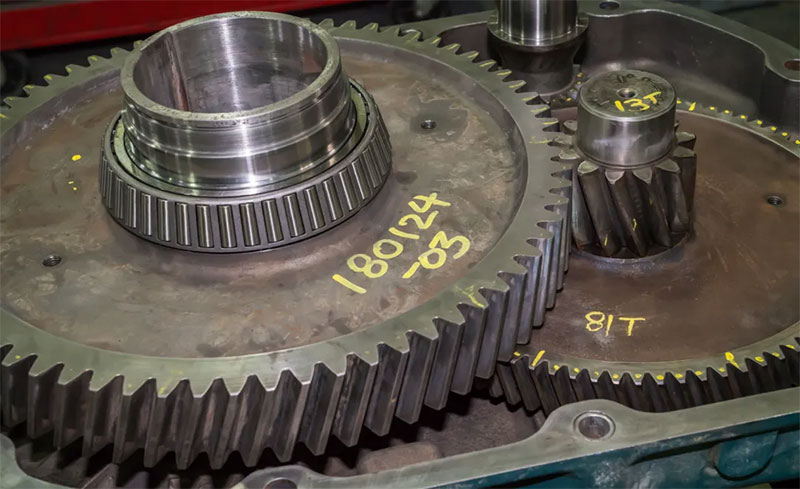

针型阀 全称针型截止阀 Needle Valve 内部结构和运行原理 为什么齿数要设计为互质数!教材只告诉我结果,却没告诉我原因

为什么齿数要设计为互质数!教材只告诉我结果,却没告诉我原因 本站所有资源一键获取,含3D模型、设计软件和案例视频等

本站所有资源一键获取,含3D模型、设计软件和案例视频等 支付宝现金红包,又疯狂“大面积”送钱了!人均 1-20 元 (无套路/每天能领)

支付宝现金红包,又疯狂“大面积”送钱了!人均 1-20 元 (无套路/每天能领) AutoCAD 2025 破解版+注册机 安装程序免费下载,附下载地址及安装教程

AutoCAD 2025 破解版+注册机 安装程序免费下载,附下载地址及安装教程 SolidWorks 2024 SP2.0 破解版免费下载及安装教程

SolidWorks 2024 SP2.0 破解版免费下载及安装教程 发那科机器人 FANUC 离线编程 动画仿真模拟软件 ROBOGUIDE V9 免费下载

发那科机器人 FANUC 离线编程 动画仿真模拟软件 ROBOGUIDE V9 免费下载