双张材料传感器 UDC-18GM50-255-3E1产品说明书百度网盘下载链接:https://pan.baidu.com/s/11Mi3ewdEOMWoEHifTsqMiw 提取码: wiq7

采用超声波检测原理,检测是否两个薄板材粘连在一起,比如常见的钣金折弯行业,需要检测棒材是否2张粘在一起。

倍加福双张材料传感器用于可靠检测无、单张或者双张重叠材料的超声波系统,更适宜检测纸。

- 不需要TEACH-IN

- 从所有角度都可以看见功能指示灯

- 对印刷物、颜色和光亮的表面不敏感

- 材料重量冲 10 g/m2 到超过 2000 g/m2

- 可检测的材料范围广,可检测纸、薄的金属以及塑料和金属薄膜

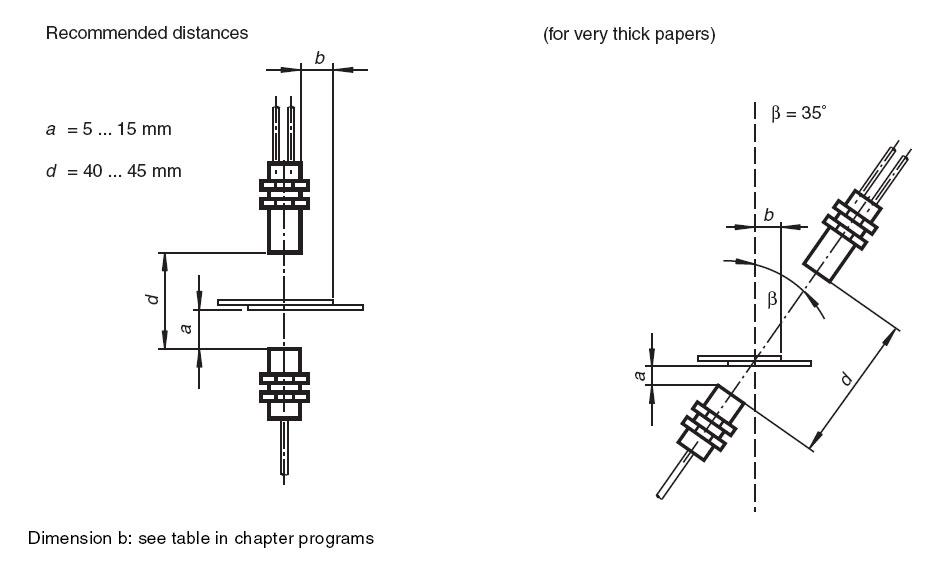

- 根据不同的检测面需要可垂直或倾斜安装传感器

- 参数可选

Description of sensor functions

The ultrasonic double sheet monitor (UDC) is used in all situations in which the automatic distinction between single and double sheets is required in order to protect machines or avoid waste production. The double sheet monitor is based on the ultrasonic through-beam principle. The following can be detected:

- No sheet, i. e. air

- Individual sheet

- Double sheet or multiple sheets (no distinction can be made for the numberof sheets)

A microprocessor system evaluates the signals. The appropriate switch outputs are set as a result of the evaluation. Changes in ambient conditions such as temperature and humidity are compensated for automatically.

Working principle

The measuring principle of the double sheet control is based on measuring and evaluating the transmitted sound amplitude through a sheet of paper. If there is no paper, no sound is absorbed and the received signal reaches its maximum level. If there are two sheets of paper, one on top of the other, almost all of the signal is absorbed due to multiple reflection between the layers.

The amplitude of the signal passing through thus reaches a minimum level.

The thicker or denser a given type of paper is, the lower the portion of sound that will pass through it according to the working principle. Because of this, the functionality of the double sheet control is limited to types of paper that fall within a specific range. Paper that is too thin allows too much sound to pass through so that it is not sufficiently different from air. On the other hand, paper that is too thick absorbs so much of the sound that the amplitude for single sheets is already in the range of a double sheet.

Therefore, the double sheet control offers the user 4 different programs for different ranges of material, making it possible to adjust to the ideal setting for different applications. There is no need to perform TEACH-IN for single sheet. This makes the product more user-friendly. Fluttering movements of the paper do not affect reliable operation of the UDC.

Function input

Function input (wire colour pink, PK) is used to adjust the sensor and assign

parameters to it. The following functions are available:

- Alignment aid

- Program selection

- Output pulse extension

During normal operation, the function input must always be securely connected with +UB or -UB, to avoid possible interference or improper functionality.

Measuring system

A complete unit consists of an ultrasonic emitter unit and an evaluation and receiver unit. The sensor heads are optimally adjusted to each other when they leave the factory. Therefore, they should not be used separately or exchanged with other devices of the same type. The plug connector on the emitter/receiver connection cable is only intended to be used for easier mounting,not to replace units.

Installation and adjustment

Correct functionality of the sensor can only be ensured if the emitter and receiver are adjusted so they are exactly centred on each other. This condition is automatically fulfilled if the MH-UDB01 mounting aid (see chapter 8 "Accessories" on page 16) is used. In addition, the UDC-18GM50 offers an electronic alignment aid (see chapter 6.6.1 "Alignment aid" on page 11).

Recommended spacing between the sensor heads:d = 40 mm ... 45 mm

Angular misalignment: α < +/- 1°

Maximum misalignment: s < +/- 1 mm

转载请注明:

文章作者: 任鸟飞 原文链接:https://www.cad2d3d.com/post-1032.html

留言说明:

如对本文有疑问,可关注微信公众号 科技大爆炸 从0到1 直接留言即可。手机扫描下方二维码直接关注 科技大爆炸 从0到1。

也可以直接发邮件给我,我的邮箱18036678070@cad2d3d.com

远程安装机械设计各类画图软件3D软件视频编辑软件SW安装远程服务

远程安装机械设计各类画图软件3D软件视频编辑软件SW安装远程服务

远程安装SW设计库国标非标机械设计库模型库SOLIDWORKS直接生成

远程安装SW设计库国标非标机械设计库模型库SOLIDWORKS直接生成

SolidWorks2012-2025软件安装U盘3d画图软件机械设计建模软件优盘

SolidWorks2012-2025软件安装U盘3d画图软件机械设计建模软件优盘

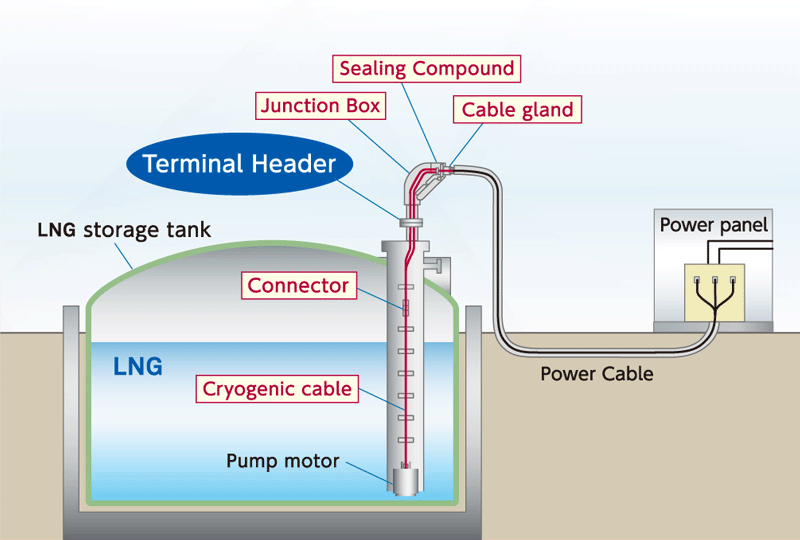

LNG罐内泵电气终端接头(接线端子)内部构造、绝缘和密封

LNG罐内泵电气终端接头(接线端子)内部构造、绝缘和密封

![你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]](https://www.cad2d3d.com/uploads/202601/ranqibiao.jpg) 你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]

你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]

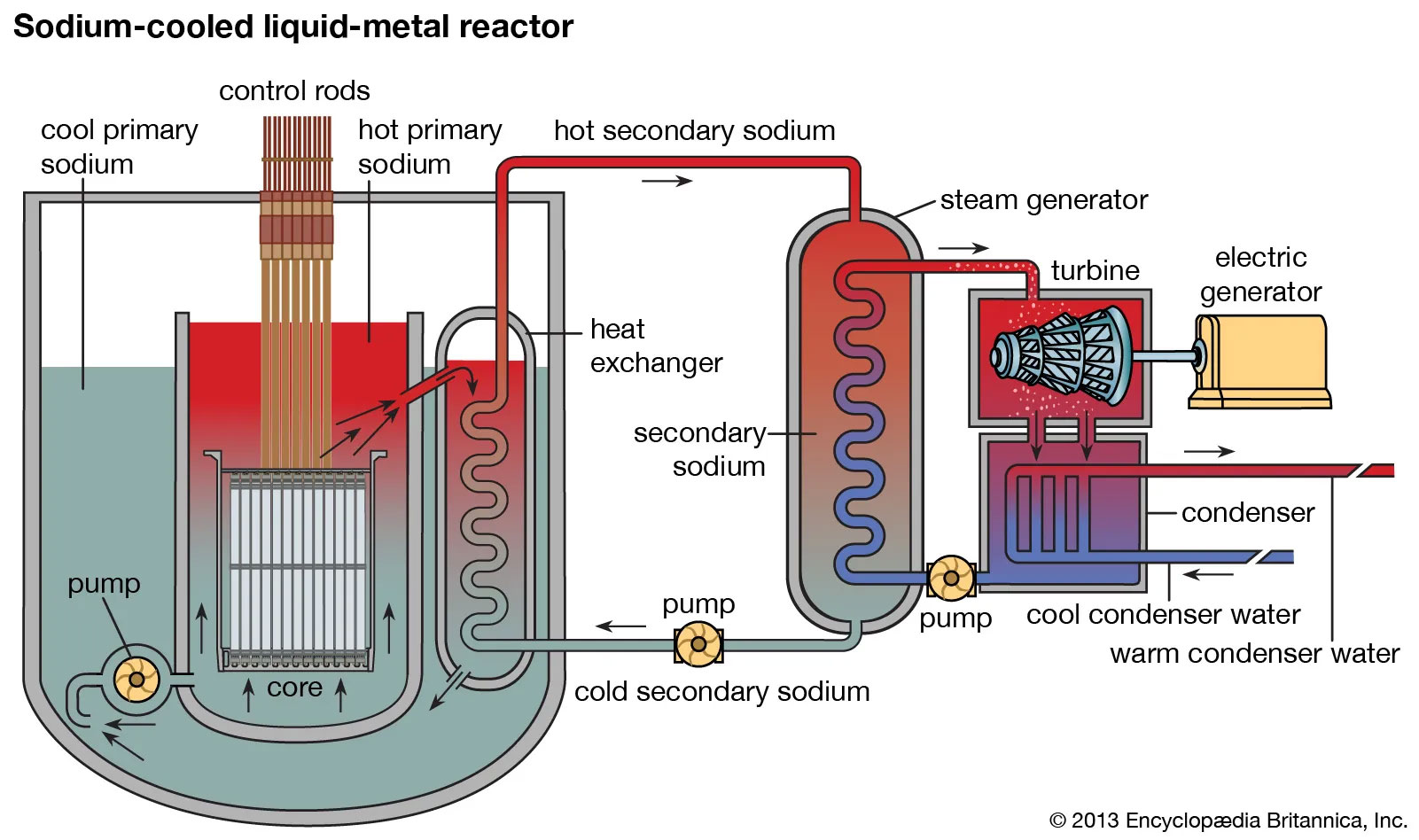

核电站运行原理及核岛常规岛主设备高清图

核电站运行原理及核岛常规岛主设备高清图

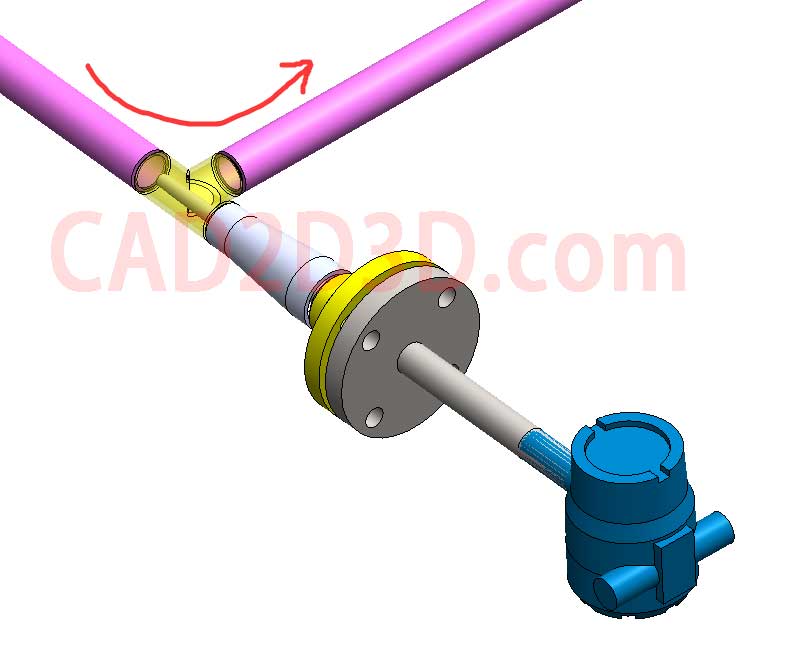

管道热电阻(热电偶)安装方法,温度变送器安装位置,一图胜过千言万语

管道热电阻(热电偶)安装方法,温度变送器安装位置,一图胜过千言万语

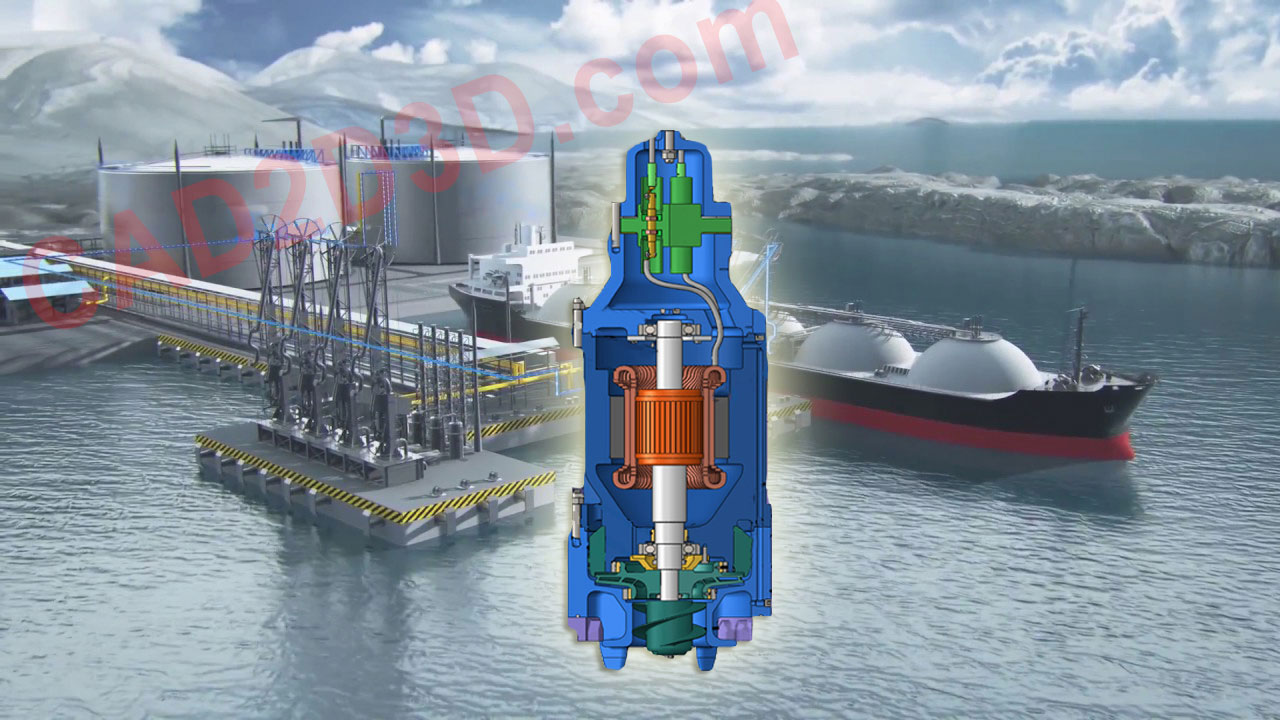

LNG罐内泵(低温潜液泵)内部构造、结构组成和运行原理

LNG罐内泵(低温潜液泵)内部构造、结构组成和运行原理

油罐液压潜液泵内部构造、组成和实物图

油罐液压潜液泵内部构造、组成和实物图

本站所有资源一键获取,含3D模型、设计软件和案例视频等

本站所有资源一键获取,含3D模型、设计软件和案例视频等 支付宝现金红包,又疯狂“大面积”送钱了!人均 1-20 元 (无套路/每天能领)

支付宝现金红包,又疯狂“大面积”送钱了!人均 1-20 元 (无套路/每天能领) AutoCAD 2025 破解版+注册机 安装程序免费下载,附下载地址及安装教程

AutoCAD 2025 破解版+注册机 安装程序免费下载,附下载地址及安装教程 SolidWorks 2024 SP2.0 破解版免费下载及安装教程

SolidWorks 2024 SP2.0 破解版免费下载及安装教程 发那科机器人 FANUC 离线编程 动画仿真模拟软件 ROBOGUIDE V9 免费下载

发那科机器人 FANUC 离线编程 动画仿真模拟软件 ROBOGUIDE V9 免费下载