莱斯安全阀对安全阀的安装位置说明如下:

6.2.4 Location of the Safety Valve(安全阀安装位置)

6.2.4.1 Distance to Pressure Source(距离压力源)

The safety valve should normally be placed close to the protected equipment so that the pressure losses to the safety valve are within the allowable limits. For example, where protection of a pressure vessel is involved, mounting the safety valve directly on top of the vessel is suggested. However, on installations that have pressure fluctuations at the pressure source (as with valves on the compressor discharge) that peak close to the set pressure of the safety valve, the safety valve should be located farther from the source (e.g. behind a compressed air chamber) and in a more stable pressure region.(来自:API RP 520 Part II, 5 th Edition 2003, Sect. 9.2)(安全阀通常应放置在靠近受保护设备的位置,以便安全阀的压力损失在允许的范围内。例如,当涉及保护压力容器时,建议将安全阀直接安装在容器顶部。但是,在压力源处存在压力波动的装置(如压缩机出口处的阀门)峰值接近安全阀的设定压力时,安全阀应位于离源更远的地方(例如,在压缩空气室后面)和更稳定的压力区域)

6.2.4.2 Distance to Other Valve Equipment(距离其他阀门设备的)

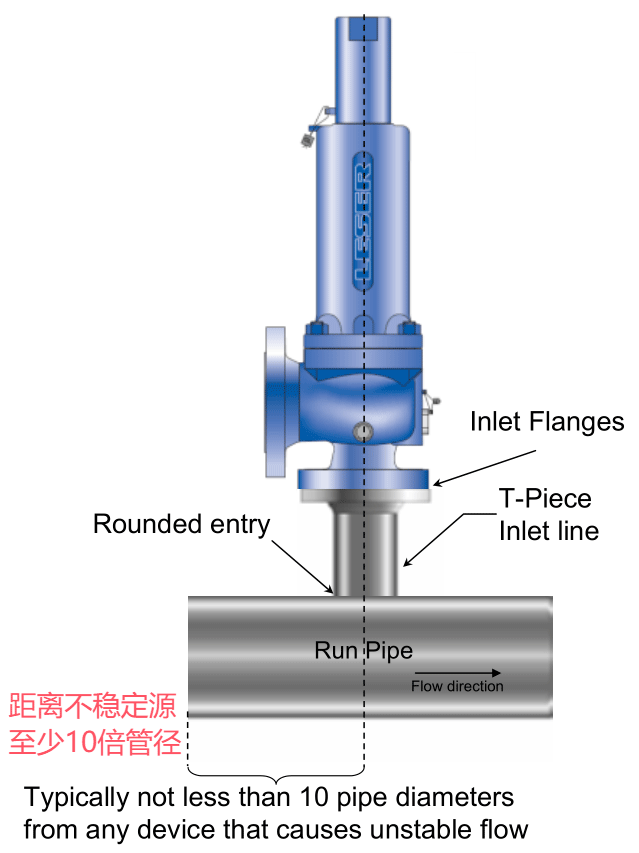

The safety valves should not be located where unstable flow patterns are present (Figure 6.2.4.2-1).(安全阀不应位于存在不稳定流型的地方)

The branch entrance where the safety valve inlet line joins the main piping run should have a well rounded, smooth corner that minimizes turbulence and resistance to flow.(来自 API RP 520 Part II, 5 th Edition 2003, Sect. 9.3)(安全阀入口管线与主管道连接处的支入口应有一个圆润、光滑的拐角,以最大限度地减少湍流和流动阻力。)

Figure 6.2.4.2-1: Distance to other valve equipment acc. to API 520 part II

6.2.4.3 Sources of Irritation(敏感源)

Safety valves are often used to protect piping downstream from pressure reducing valves or control valves, where unstable flow usually occurs. Other valves and equipment in the system may also disturb the flow. This condition cannot be evaluated readily, but unsteady flow at valve inlets tends to generate instability. Therefore safety valves should be installed at least 10 pipe diameters away from the source of irritation.(来自 API RP 520 Part II, 5 th Edition 2003, Sect. 9.3.1)(安全阀通常用于保护下游管道免受减压阀或控制阀的影响,这些减压阀或控制阀通常会出现不稳定的流量。系统中的其他阀门和设备也可能干扰流动。这种情况无法轻松评估,但阀门入口处的不稳定流动往往会产生不稳定。因此,安全阀应安装在距离刺激源至少 10 个管径的地方。)

The proximity to orifice plates and flow nozzles may cause adverse performance of the safety valves. Also the use of other fittings, such as elbows, may create turbulent areas that could have an impact on the safety valve’s performance.(API RP 520 Part II, 5 th Edition 2003, Sect. 9.3.2)(靠近孔板和流量喷嘴可能会导致安全阀性能不佳。此外,使用其他配件,如弯头,可能会产生湍流区域,从而影响安全阀的性能。)

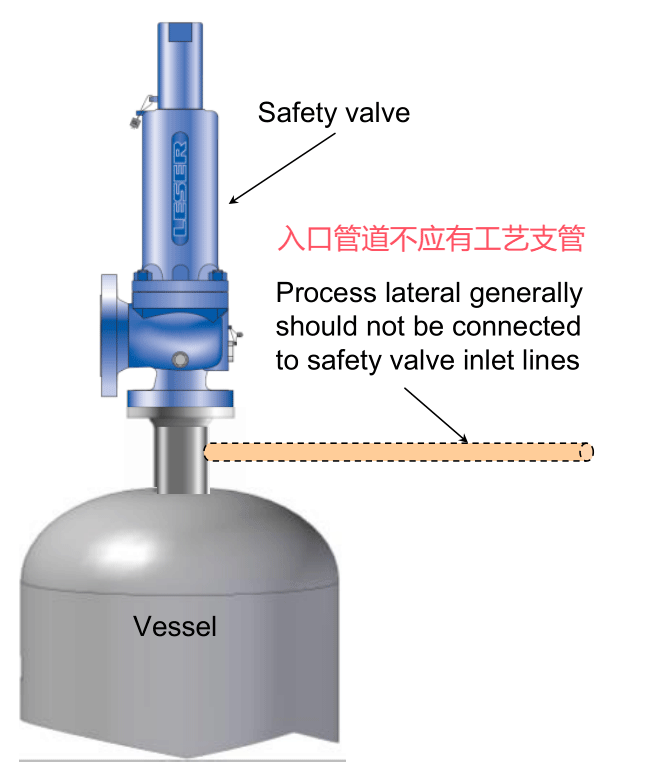

6.2.4.4 Process Laterals Connected to the Inlet Line of Safety Valves(工艺管道不应连接到安全阀入口管线上)

“Process laterals should generally not be connected to the inlet line of safety valves. Exceptions should be analyzed carefully to ensure that the allowable pressure loss at the inlet of the safety valve is not exceeded under simultaneous conditions of rated flow through the safety valve and maximum possible flow through the process lateral (Figure 6.2.4.4-1).(来自 API RP 520 Part II, 5 th Edition 2003, Sect. 4.7)

Figure 6.2.4.4-1: Process lateral acc. to API 520 part II

6.3 Plant Design – Inlet Line(入口管线)

Within this section requirements regarding the inlet line of safety valves within the specific plant design are characterized. Several codes and standards deal with this subject and have very similar conclusions. API 520 Part II is very detailed with its description and is the basis for the statements in this section. In cases where other codes and standards differ from statements in API 520 Part II,

these differences will be explained. Other referenced codes and standards are:

- DIN EN ISO 4126-9

- AD 2000-Merkblatt A2

- ASME Section VIII Division 1

6.3.1 Correct Sizing of the Inlet Line(入口管线尺寸)

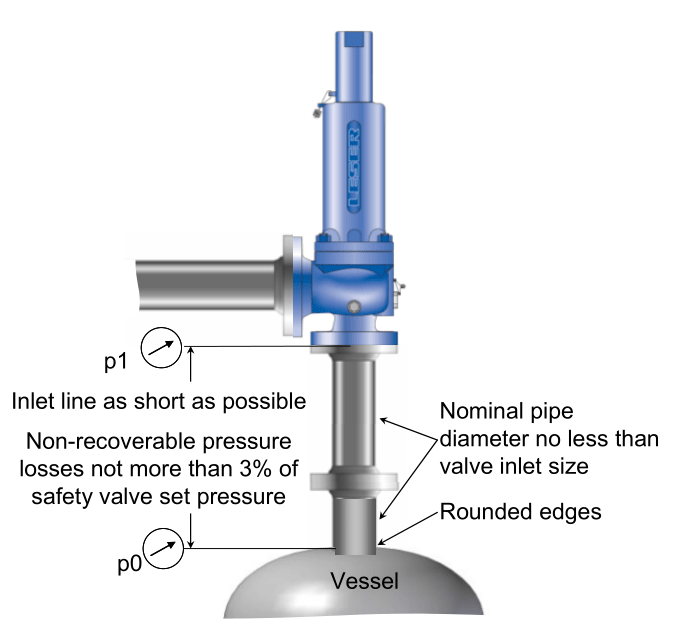

To size and design an inlet line properly the following aspects have to be considered.(安全阀入口管线尺寸设计需要考虑以下事项)

1. The pressure loss shall not exceed 3%. The following measures help to fulfill this requirement(压力损失不得超过 3%。以下措施有助于满足此要求):

- The inlet line should be as short and straight as possible(入口管线应尽可能短而直)

- Nominal pipe diameter equal or larger than valve inlet size(入口管线公称直径等于或大于阀门入口尺寸)

- Rounded edges at the entrance to the inlet line(入口管路入口处的圆角边缘)

2. Stress should be avoided.(避免附加应力)

3. Vibrations in the inlet line should be avoided.(避免入口管线震动)

4. The inlet line should be free-draining(入口管线应为自由排水管路)

Figure 6.3.1-1: General guidelines for inlet lines

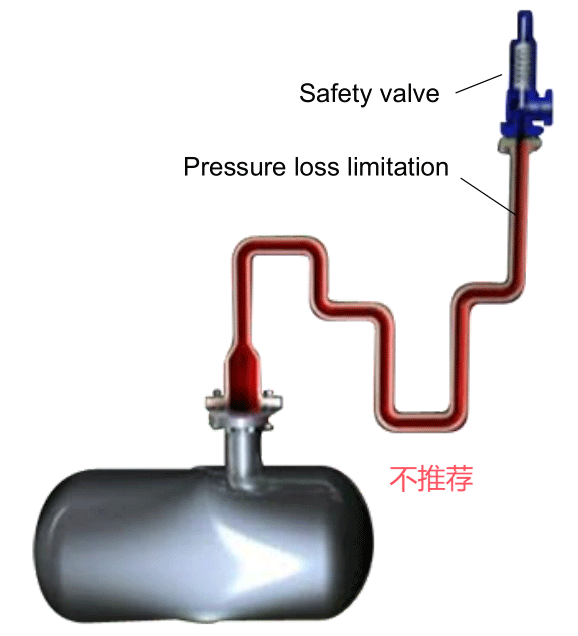

6.3.2.1 Unfavourable Size, Length and Configuration of Inlet Lines(入口管线不应该这样设置)

Figure 6.3.2.1-1: Incorrect sizing of inlet line

Incorrect sizing can cause excessive pressure loss. The following configurations are unfavourable(尺寸不正确会导致压力损失过大。以下配置是不利的):

- Long inlet line with several bends, elbows or other equipment installed before the safety valve(在安全阀之前安装多个折弯、弯头或其他设备的长入口管线)

- Too small inlet line size(入口管线尺寸太小)

- Sharp edges at the entrance to the inlet line(入口管路入口处的锋利边缘)

参考文献:https://www.leser.com/-/media/Files/Engineering/Chapters/LID_DE_175706_EN_EHB_06_Installation%20and%20plant%20design

转载请注明:

文章作者: 尚延伟 原文链接:https://www.cad2d3d.com/post- 2159 .html

可能感兴趣的文章

正在加载你可能感兴趣的文章...

更多最新发布: 化工装备

-

GB 50093 自动化仪表工程施工及质量验收规范 温度、压力取源部件安装规定、条文解释说明及案例解析

-

电气装置应接地,螺栓应有防松装置,接线端子及紧固件应涂电力复合脂

-

钢厂作业人员必备!饱和水蒸气球罐(球形蒸汽蓄热器)技术参数、生产制造过程、实物图及潜在失效模式分析

钢厂作业人员必备!饱和水蒸气球罐(球形蒸汽蓄热器)技术参数、生产制造过程、实物图及潜在失效模式分析

-

绝了!LNG 工厂的终极神器竟然是自行车,电器全封杀,机械的含金量还在上升

绝了!LNG 工厂的终极神器竟然是自行车,电器全封杀,机械的含金量还在上升

-

LPG、丙烷、丁烷等装卸车用 STANAG 3756 干式分离阀(干式快速接头)厂家品牌及产品介绍

LPG、丙烷、丁烷等装卸车用 STANAG 3756 干式分离阀(干式快速接头)厂家品牌及产品介绍

-

LNG 罐箱(罐式集装箱) P&ID、阀门清单、3D效果图、实物图和装卸方法

LNG 罐箱(罐式集装箱) P&ID、阀门清单、3D效果图、实物图和装卸方法

-

API 610 离心泵的泵型 OH1 和 OH2 的区别、图示及对应的实物图

API 610 离心泵的泵型 OH1 和 OH2 的区别、图示及对应的实物图

-

![你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]](https://www.cad2d3d.com/uploads/202601/ranqibiao.jpg) 你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]

你家燃气耐烧吗?燃气表入口压力对计量结果影响巨大,极端情况下计量结果相差2倍, [勘误:绝对压力波动很小,对体积影响很小,对计量结果的影响可以忽略不计]

SW SolidWorks软件远程安装2025/2024/2023/2022/2021/2020/2

SW SolidWorks软件远程安装2025/2024/2023/2022/2021/2020/2  1.4万套solidworks非标自动化设备3D图纸机械设计SW建模三维模型

1.4万套solidworks非标自动化设备3D图纸机械设计SW建模三维模型  SW SolidWorks软件远程安装2026/2025/2024/2023/2022/2021/2

SW SolidWorks软件远程安装2026/2025/2024/2023/2022/2021/2

本站所有资源一键获取,含3D模型、设计软件和案例视频等

本站所有资源一键获取,含3D模型、设计软件和案例视频等 支付宝现金红包,又疯狂“大面积”送钱了!人均 1-20 元 (无套路/每天能领)

支付宝现金红包,又疯狂“大面积”送钱了!人均 1-20 元 (无套路/每天能领) AutoCAD 2025 破解版+注册机 安装程序免费下载,附下载地址及安装教程

AutoCAD 2025 破解版+注册机 安装程序免费下载,附下载地址及安装教程 SolidWorks 2024 SP2.0 破解版免费下载及安装教程

SolidWorks 2024 SP2.0 破解版免费下载及安装教程 发那科机器人 FANUC 离线编程 动画仿真模拟软件 ROBOGUIDE V9 免费下载

发那科机器人 FANUC 离线编程 动画仿真模拟软件 ROBOGUIDE V9 免费下载