装卸臂概述

O PW% LOADING ARM OVERVIEW

a I, company

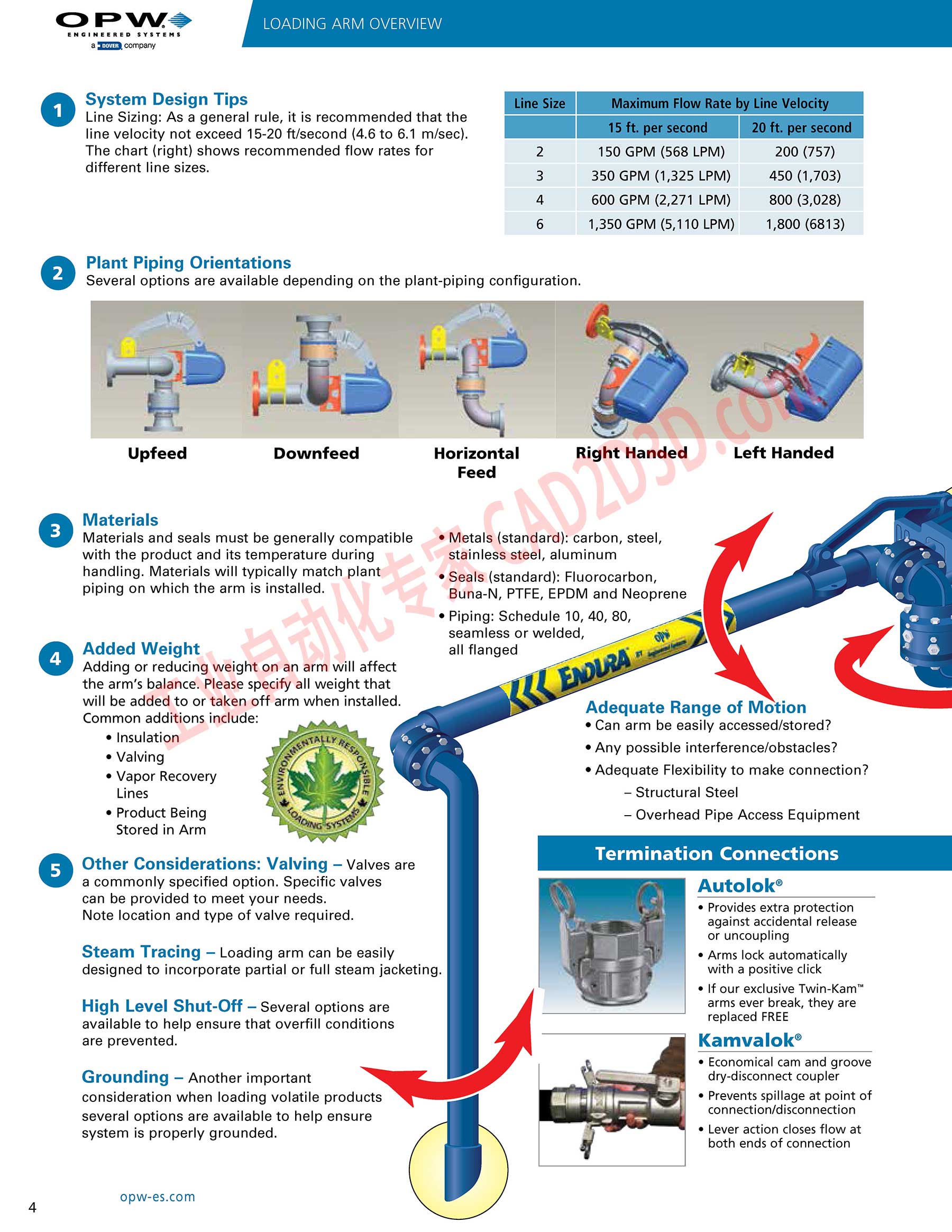

System Design Tips

Line Sizing: As a general rule, it is recommended that the =___

line velocity not exceed 15-20 ft/second (4.6 to 6.1 m/sec).

The chart (right) shows recommended flow rates for 2 150 GPM (568 LPM) 200 (757)

differentiline sizes. 3 350 GPM (1,325 LPM) 450 (1,703)

4 600 GPM (2,271 LPM) 800 (3,028)

6 1,350 GPM (5,110 LPM) 1,800 (6813)

Plant Piping Orientations

Several options are available depending on the plant-piping configuration.

Upfeed Downfeed Horizontal Right Handed Left Handed

Feed

Materials

Materials and seals must be generally compatible ® Metals (standard): carbon, steel,

with the product and its temperature during stainless steel, aluminum

handling. Materials will typically match plant 。Seals (standard): Fluorocarbon ,

piping on which the arm is installed. Buna-N, PTFE, EPDM and Neoprene

s。Piping: Schedule 10, 40, 80,

seamless or welded,

Added Weight all flanged

Adding or reducing weight on an arm will affect

the arm’s balance. Please specify all weight that

will be added to or taken off arm when installed.

Common additions include:

Adequate Range of Motion

* Can arm be easily accessed/stored?

¢ Insulation

« Valving ¢ Any possible interference/obstacles?

« Vapor Recovery * Adequate Flexibility to make connection?

Lines — Structural Steel

¢ Product Being

Stored in Arm

— Overhead Pipe Access Equipment

Termination Connections

Autolok®

* Provides extra protection

against accidental release

or uncoupling

* Arms lock automatically

with a positive click

o If our exclusive Twin-Kam™

arms ever break, they are

replaced FREE

Kamvalok®

* Economical cam and groove

= - dry-disconnect coupler

* Prevents spillage at point of

connection/disconnection

e Other Considerations: Valving — Valves are

a commonly specified option. Specific valves

can be provided to meet your needs.

Note location and type of valve required.

Steam Tracing — Loading arm can be easily

designed to incorporate partial or full steam jacketing.

High Level Shut-Off — Several options are

available to help ensure that overfill conditions

are prevented.

Grounding — Another important

consideration when loading volatile products

several options are available to help ensure

system is properly grounded.

LR ——I\P]

o Lever action closes flow at

both ends of connection

opw-es.com

�